High-temperature Condensate Water

Boilers consume a significant amount of steam, but only condensate water can be recovered and reused. If most of the condensate water can be recycled, it will generate tremendous economic and environmental benefits. In atmospheric boilers, the temperature of the condensate return water is above 40°C, while in medium-pressure boilers, the return water temperature reaches over 150°C, making the value of recycled water and energy extremely high.

Untreated condensate water generally contains a certain amount of impurities, originating from condenser leaks, corrosion of thermal equipment metals, and residual impurities in boiler makeup water. Most of the suspended solids in condensate water are insoluble, such as corrosion products like iron oxide and iron hydroxide, which cannot be removed through ion exchange. If the corrosion products in condensate water are not treated, they will be sent to the boiler and deposit in areas with high heat loads, forming iron scale, which can affect the heat transfer and safe operation of the boiler tubes.

Purpose of Separation

● Prefiltration: To remove residual impurities, colloids, and particles from the water.

● Iron Removal Filtration: To remove corrosion products from the water, enabling the reuse of condensate water.

Filtration Requirements

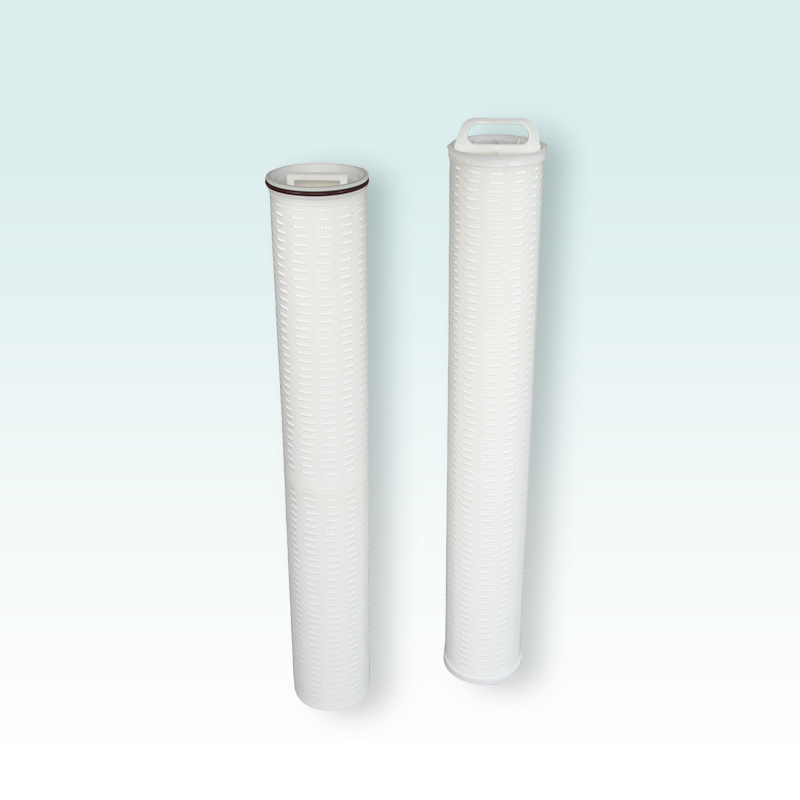

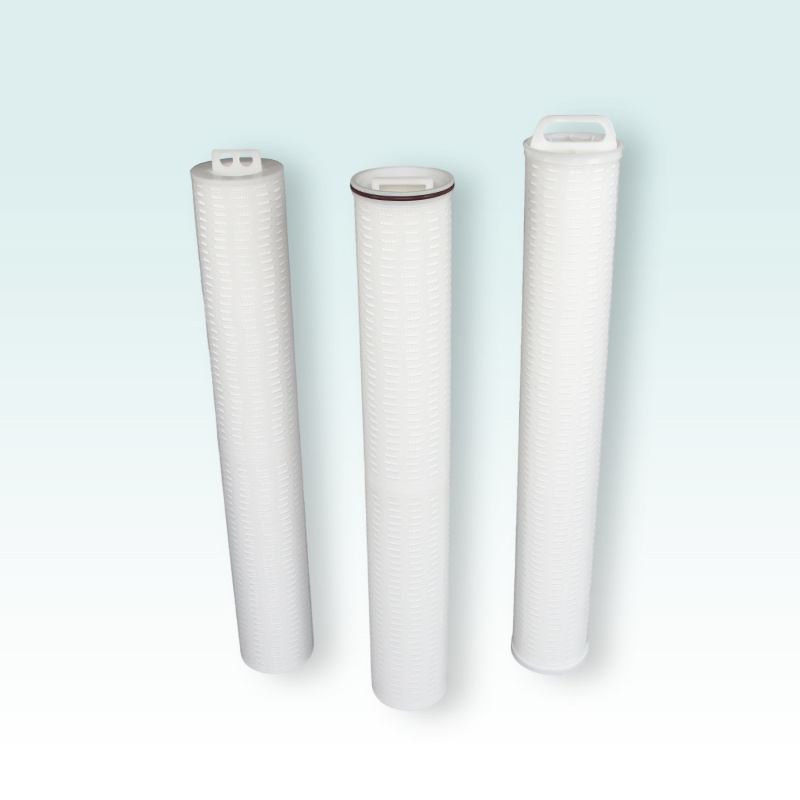

● High-temperature resistant filter cartridges.

● Simple equipment construction, easy operation, and convenient maintenance.

● Reliable operation, compact equipment design, and automatic backwashing capabilities.

● Optional deep-bed filter media cartridges with high dirt-holding capacity and long service life.

Recommended Products

SAF Coolest v1.3.1.2 设置面板 FWVSX-AEVY-OSSQE-AFA

无数据提示

Sorry, the current column is being updated, please look forward to it!

You can view other columns or returnHome Page